Heat treatment

Heat treatment is a field of technology that encompasses a number of procedures resulting in improvement of mechanical, physical and chemical properties of metal and alloys caused by structural alterations in the solid state resulting from temperature changes, passage of time and influence of the environment. Every heat treatment process consists of operations and procedures. A heat treatment operation is a part of technological process (e.g. tempering, annealing) performed in a continuous manner, usually at a single workstation. A procedure, on the other hand, means a part of the operation (e.g. heating, soaking, cooling).

Heat treatment is a field of technology that encompasses a number of procedures resulting in improvement of mechanical, physical and chemical properties of metal and alloys caused by structural alterations in the solid state resulting from temperature changes, passage of time and influence of the environment. Every heat treatment process consists of operations and procedures. A heat treatment operation is a part of technological process (e.g. tempering, annealing) performed in a continuous manner, usually at a single workstation. A procedure, on the other hand, means a part of the operation (e.g. heating, soaking, cooling).

The fundamental parameters crucial for phase transitions include: heating rate, soaking temperature, heating, soaking and cooling time and cooling rate depending on the soaking temperature. The heating and cooling of material may take place in a continuous or gradual manner.

Local

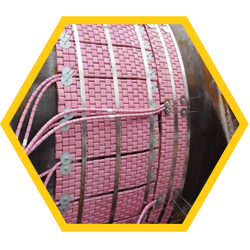

Local heat treatment is a procedure that we carry out at a construction site or at the Client’s premises with the use of technologically advanced mobile 12-channel electric heating resistors (possibility of connecting up to 24 heating mats) that enable carrying out a wide array of procedures in a wide range of materials, diameters and wall thicknesses, such as:

-

Preheating for welding

-

Post-welding heat treatment (PWHT)

-

Many other various procedures

Consumables

-

ceramic and mineral thermal insulation mats,

-

ceramic fabrics for heating,

-

type K thermocouple for both low and high temperature,

-

heating mats,

-

compensation cables,

-

plugs for cables and heating mats,

-

resistance wires, insulation bricks

biuro@convi-serwis.pl

biuro@convi-serwis.pl